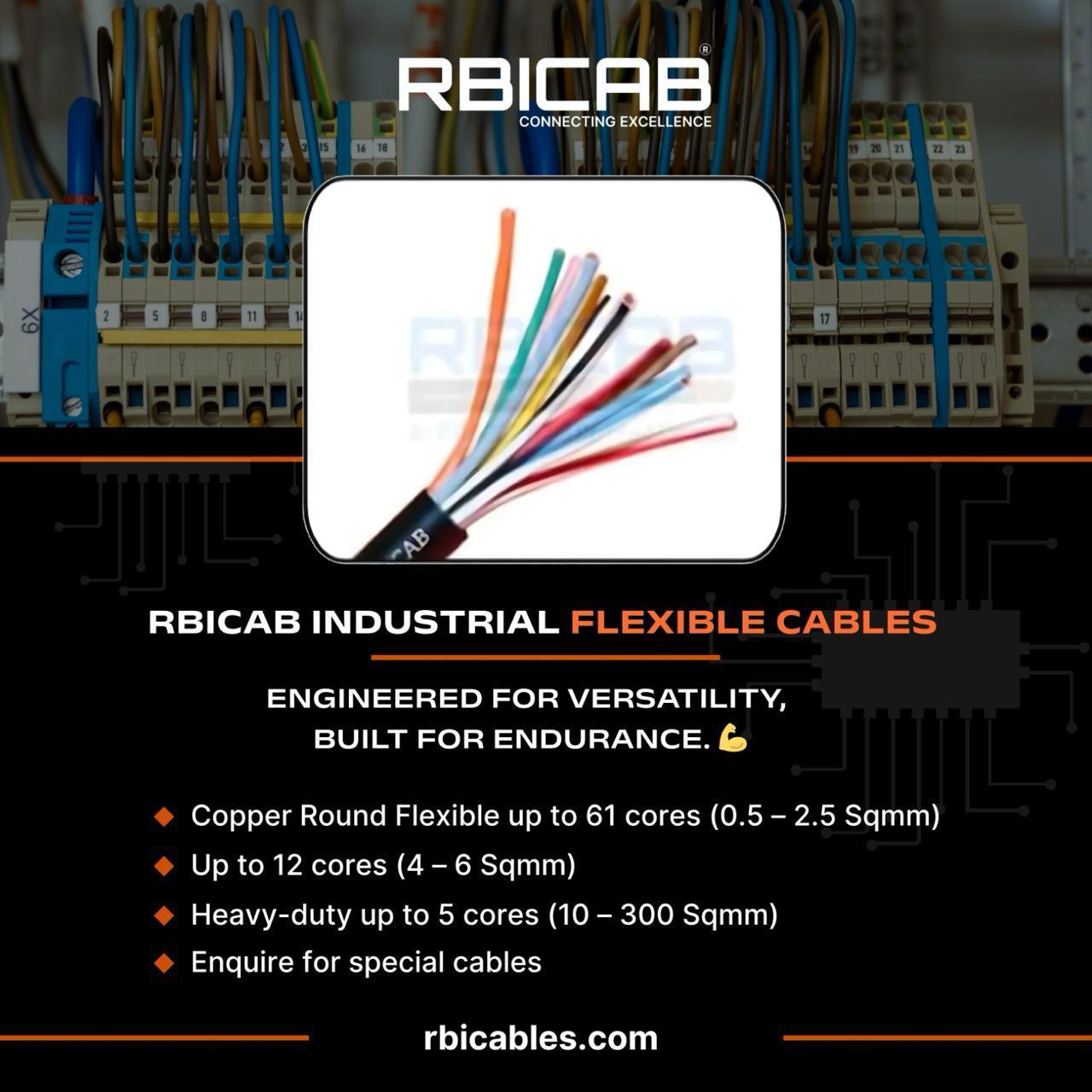

Flexible Control Wires & Cables

RBICAB Flexible Control Wires & Cables are specially engineered for

industrial and commercial applications where reliable control and signal transmission are

critical. These cables are designed to connect and control machinery, instrumentation, and

automation systems while offering high flexibility, durability, and safety in demanding

operational environments.

Manufactured with high-quality RBICAB copper conductors, these cables

ensure

excellent electrical conductivity and minimal voltage drop. The conductors are finely stranded,

providing maximum flexibility and making them ideal for use in moving equipment, robotics,

control panels, and flexible conduits.

The insulation is made from PVC, XLPE, or other high-performance

compounds, offering resistance to heat, moisture, oil, chemicals, and abrasion. This ensures

safe and reliable operation even under harsh industrial conditions. RBICAB Flexible Control

Wires &

Cables are available in single-core or multi-core configurations, allowing easy integration for

complex control circuits, signal transmission, and interconnection in automation systems.

These RBICAB cables are designed to withstand continuous flexing,

bending,

and vibration without compromising electrical performance. They comply with international

standards (IEC, IS, or equivalent), ensuring long-term reliability, safety, and performance in

industrial automation, manufacturing plants, elevators, conveyor systems, and machine tools.