Conductor : RBICAB industrial-grade multicore flexible cables employ robust electrolytic Copper conductors, stranded for high flexibility and mechanical strength. The annealing process ensures the conductors withstand constant bending and vibration typical in industrial environments.

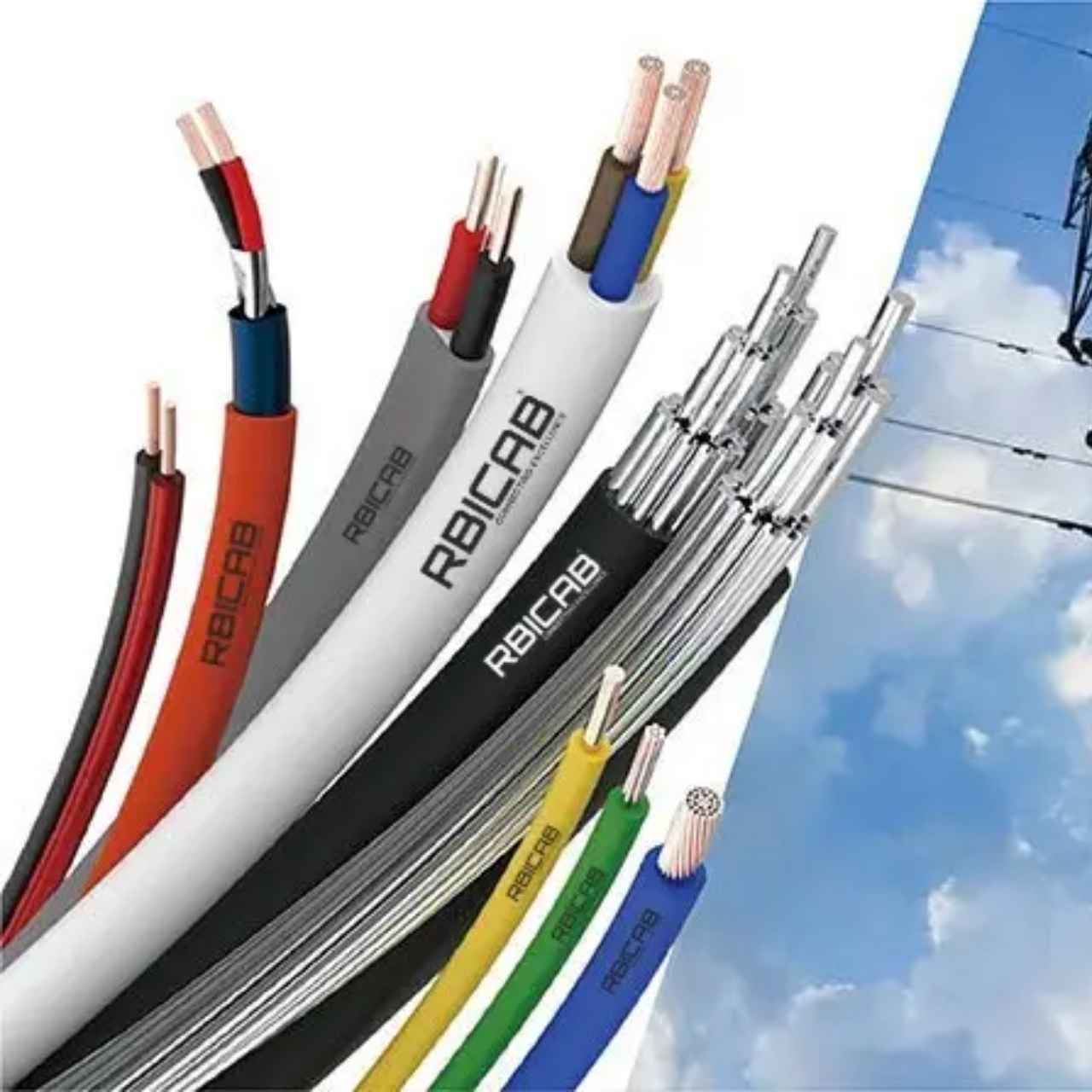

Insulation : Insulation for industrial multicore flexible cables uses heavy-duty PVC compounds with enhanced properties for toughness and chemical resistance. The cores are laid up to form a rugged, yet flexible cable structure, with color coding for easy core identification in complex industrial installations.

Quality Control : Manufacturing for industrial applications demands uncompromising standards. RBICAB enforces strict quality protocols, including thermal aging, flexibility tests, and high-voltage checks, ensuring our cables deliver safety and longevity in factories, plants, and heavy machinery.

Industrial Flexible Cables Technical Data : RBICAB industrial multicore flexible cables are built with annealed copper conductors and industrial-grade PVC insulation. They resist oils, solvents, and mechanical stress, rated for up to 1100V, making them suitable for motor wiring, control circuits, and power distribution in industrial setups.