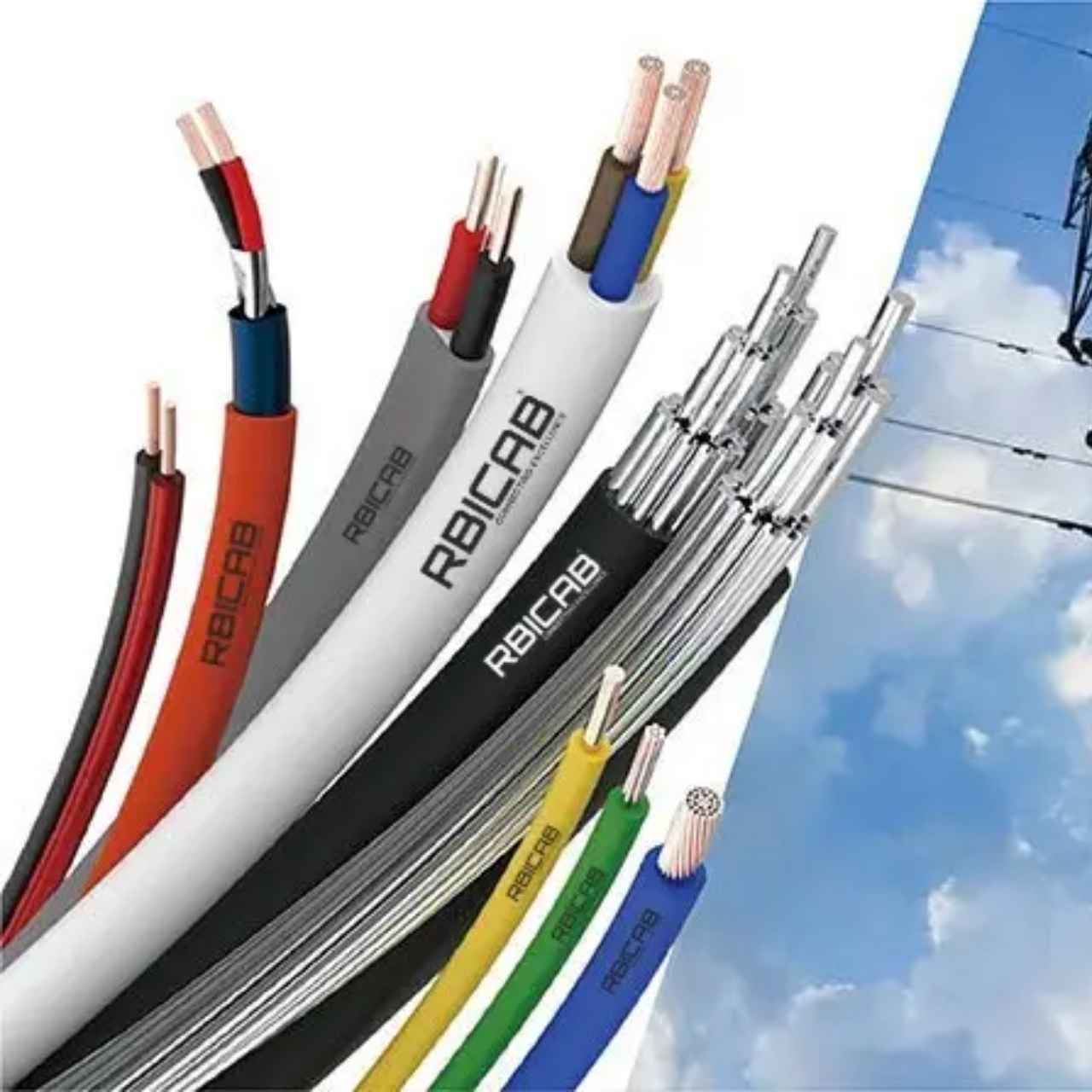

RBICAB Industrial Control Wires are engineered for demanding factory and plant environments where reliable control signal transmission is critical for operational efficiency. These wires connect sensors, actuators, controllers, and monitoring devices across industrial automation and process control systems.

Built with high-quality RBICAB copper conductors, these wires ensure consistent signal integrity and minimal electrical loss. The flexible stranded construction allows installation in areas with movement, vibration, or limited space, making them ideal for machinery, conveyor systems, and production line controls.

The robust insulation, available in materials like PVC, XLPE, or specialized industrial-grade compounds, provides resistance to oils, chemicals, moisture, and temperature variations. This protection maintains wire integrity in harsh manufacturing environments. RBICAB Industrial Control Wires support both analog and digital signal transmission for comprehensive industrial automation.

These wires are designed to perform reliably under continuous industrial operation, including exposure to mechanical stress and environmental challenges. Compliant with international standards (IEC, IS, or equivalent), they ensure safe and dependable performance in factories, processing plants, material handling systems, and industrial equipment controls.