The HRFR-LSH wires from RBICAB are premium-quality electrical wires engineered to meet modern industrial and commercial wiring standards. These wires are heat-resistant, fire-retardant (HRFR), and low-smoke halogen-free (LSH), making them the perfect choice for safe, reliable, and long-lasting electrical installations across residential, commercial, and industrial environments.

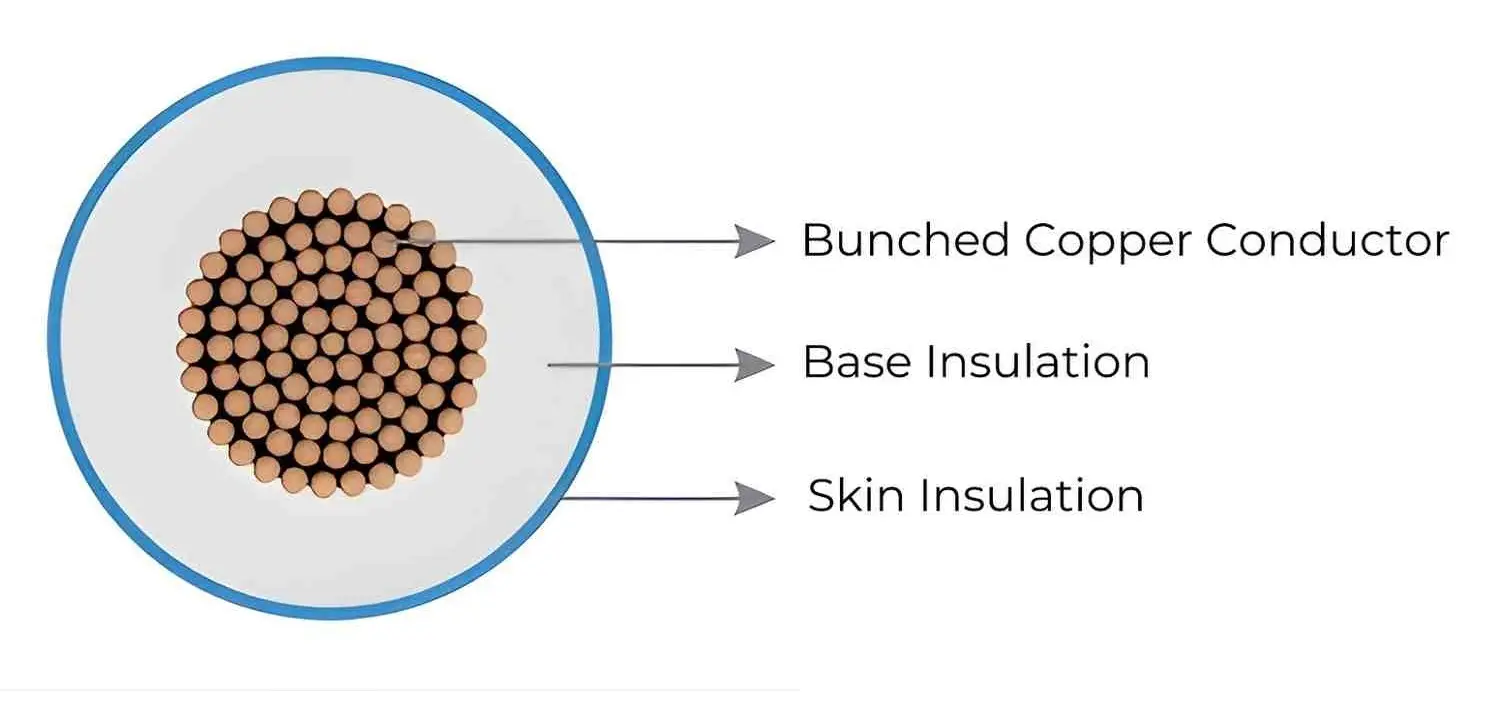

Built with high-grade copper conductors, they deliver excellent conductivity with minimal power loss. The PVC insulation ensures superior mechanical strength while offering resistance to heat, moisture, and chemical exposure. The low-smoke halogen-free design minimizes the emission of toxic fumes during fire incidents, enhancing overall safety for both people and equipment.

RBICAB’s HRFR-LSH wires are versatile and suitable for multiple applications such as panel board wiring, internal building wiring, control circuits, and installations in sensitive or high-risk areas. They strictly comply with IS:694:2010 standards and come with the ISI mark, guaranteeing quality, durability, and complete regulatory compliance.