The Heat Resistant Flame Retardant (HRFR) wires from RBICAB are premium-quality electrical wires engineered to meet modern industrial and commercial wiring standards. These wires are specifically designed for heat resistance and flame retardancy, making them the perfect choice for safe, reliable, and long-lasting electrical installations across residential, commercial, and industrial environments.

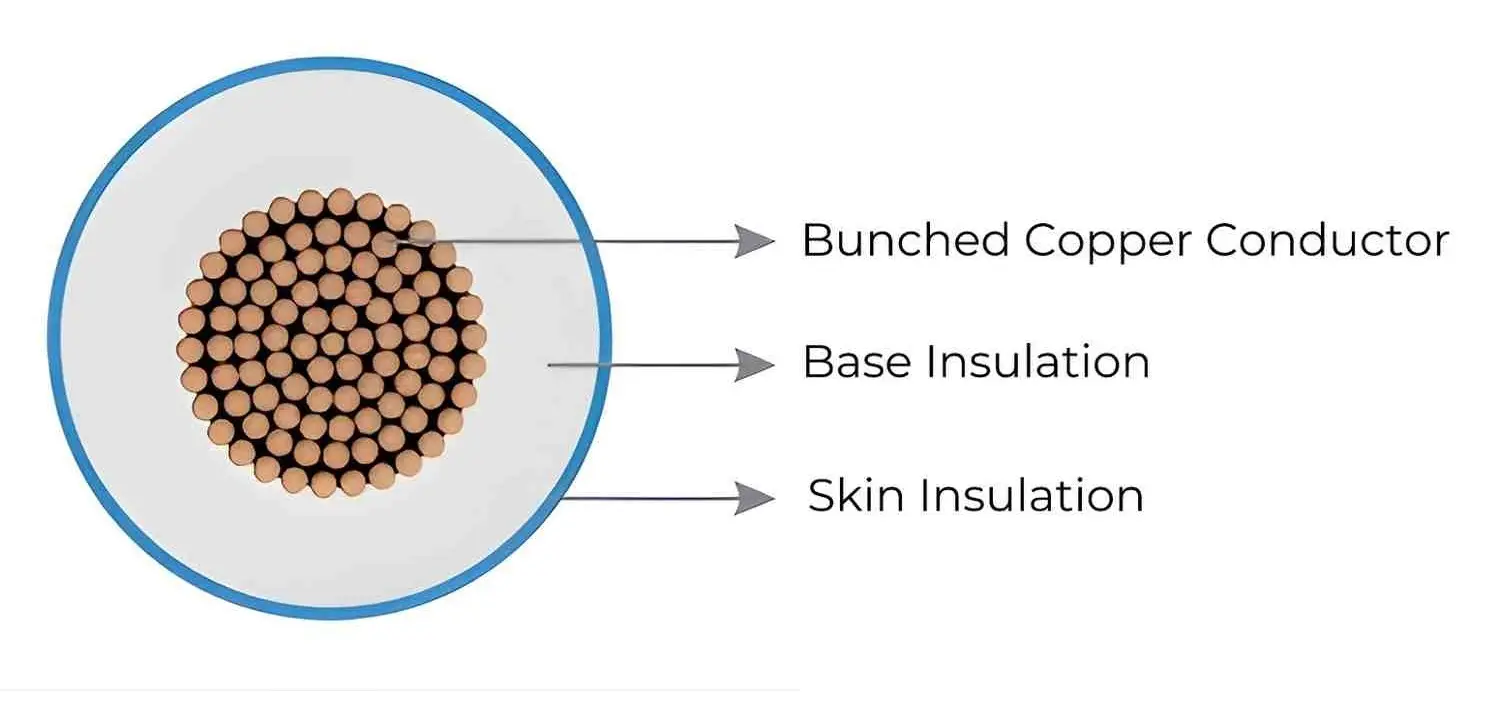

Built with high-grade copper conductors, they deliver excellent conductivity with minimal power loss. The specialized PVC insulation ensures superior mechanical strength while offering exceptional resistance to heat, moisture, and chemical exposure. HRFR wires prevent flame spread and maintain functionality in elevated temperature conditions, providing critical safety in electrical systems.

RBICAB’s Heat Resistant Flame Retardant wires are versatile and suitable for multiple applications such as panel board wiring, internal building wiring, control circuits, HVAC systems, and installations near heat sources. They strictly comply with IS:694:2010 standards and come with the ISI mark, guaranteeing quality, durability, and complete regulatory compliance.