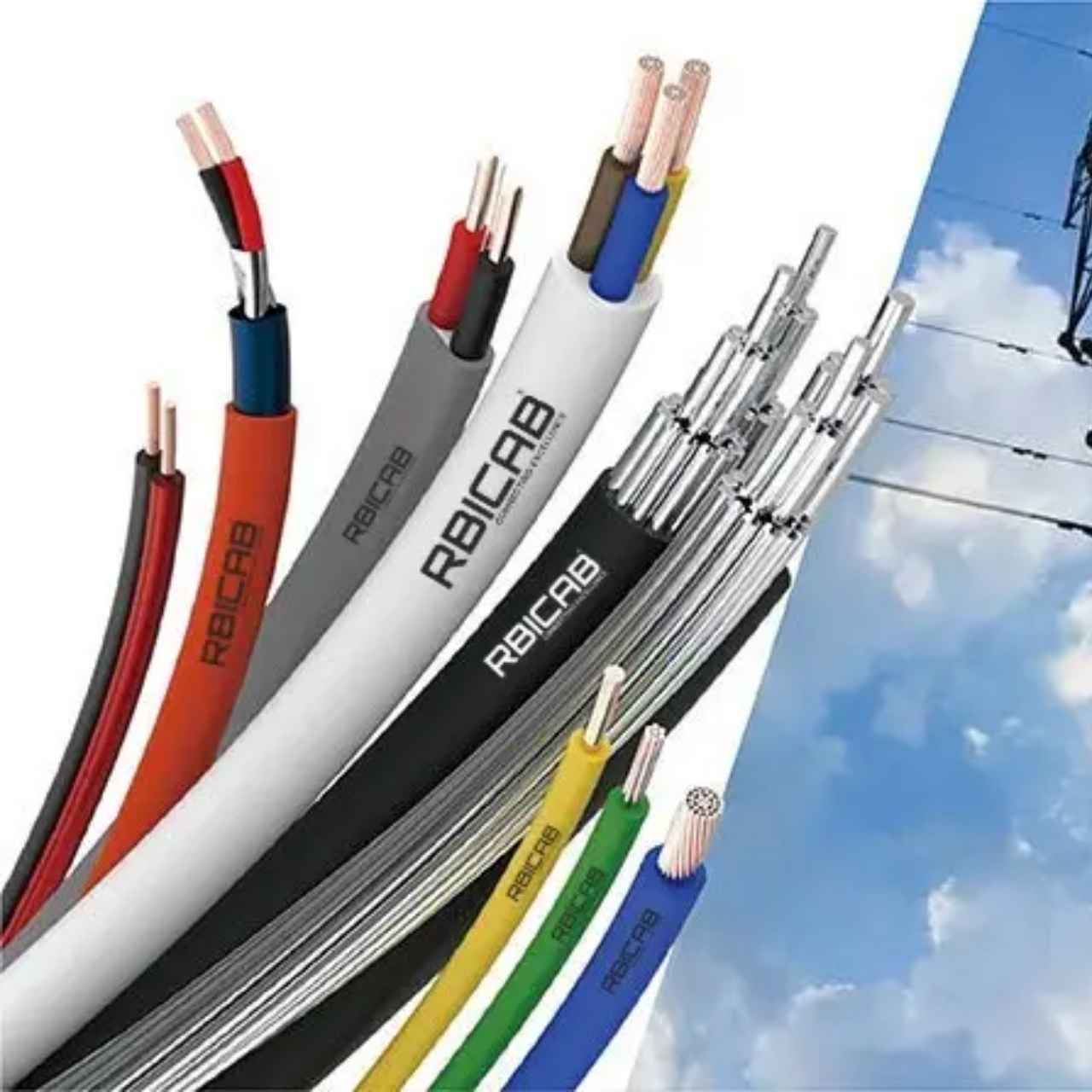

RBICAB Flexible Control Cables are engineered for precise signal transmission and equipment control in demanding industrial settings. These cables provide reliable connectivity for automation systems, machinery control, and instrumentation networks where consistent performance and durability are essential.

Constructed with high-conductivity RBICAB copper conductors, these cables ensure efficient signal transmission with minimal interference. The finely stranded design offers exceptional flexibility, making them suitable for installations in tight spaces, control panels, moving machinery, and robotic applications where frequent bending is required.

The protective insulation, available in PVC, XLPE, or specialized compounds, provides resistance against heat, moisture, oils, and chemicals. This safeguards the cable's integrity in challenging industrial environments. RBICAB Flexible Control Cables come in various core configurations to accommodate diverse control circuit requirements while maintaining reliable signal clarity.

These cables are built to endure continuous movement, vibration, and mechanical stress without performance degradation. Compliant with international standards (IEC, IS, or equivalent), they deliver dependable operation for manufacturing systems, process control, industrial machinery, and automated equipment.