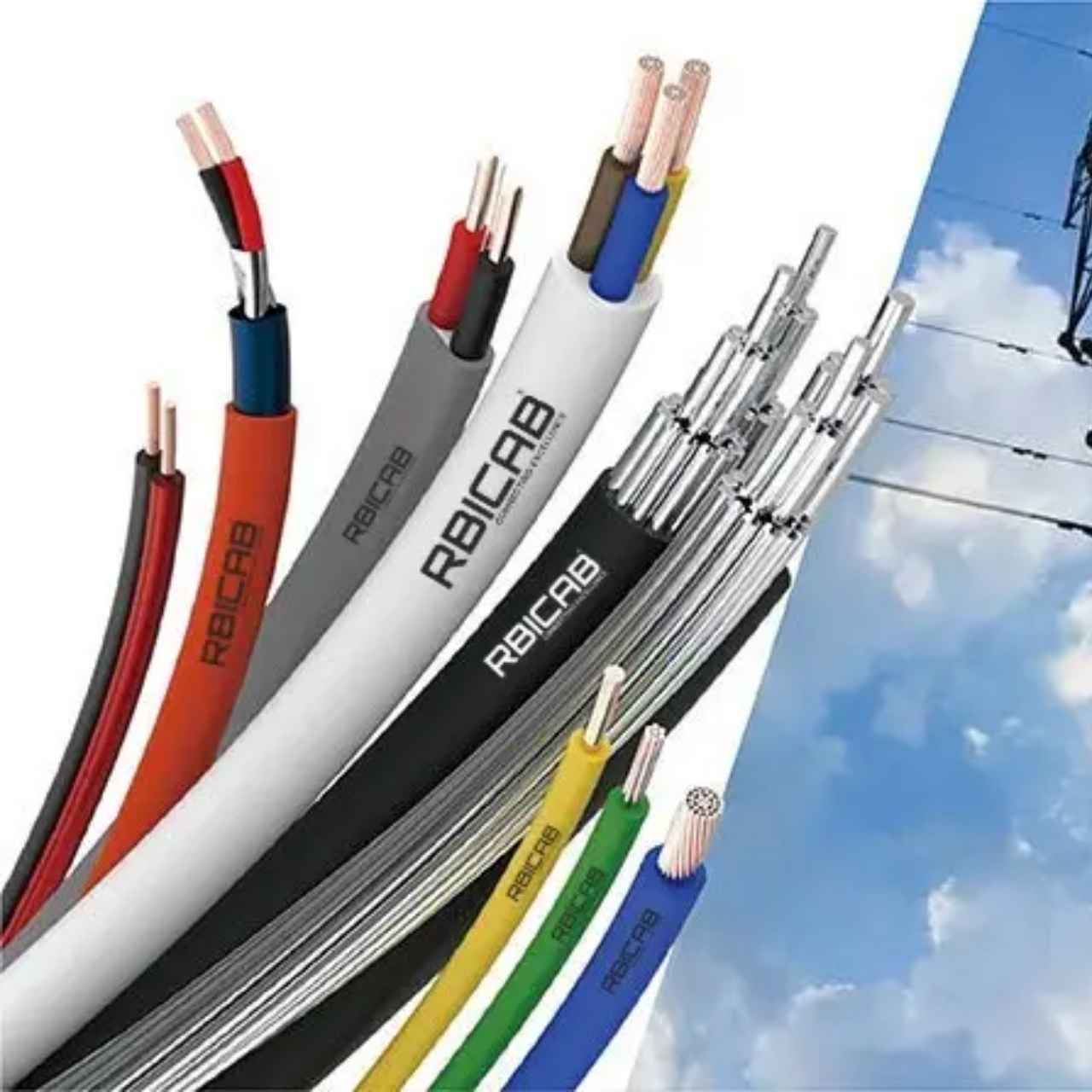

RBICAB Control Circuit Flexible Cables are designed specifically for control circuit applications where precise signal transmission and frequent movement occur. These cables connect control devices, switches, sensors, and actuators in systems requiring reliable operation under dynamic conditions.

Constructed with high-purity RBICAB copper conductors, these cables ensure accurate signal delivery for control functions. The advanced stranding provides exceptional flexibility, making them suitable for applications with continuous bending, twisting, or motion such as robotic arms, moving machinery, and automated equipment.

The specialized insulation materials, including flexible PVC and other engineered compounds, offer durability against mechanical stress, temperature fluctuations, and environmental exposure. This maintains circuit reliability in active control environments. RBICAB Control Circuit Flexible Cables are engineered to prevent signal loss or interference during movement.

These cables are optimized for control circuits that demand both electrical precision and physical adaptability. Compliant with international standards (IEC, IS, or equivalent), they deliver consistent performance in automation systems, motor controls, machinery interfaces, and other applications where control circuits experience regular motion or repositioning.